A heavy duty truck mounted crane delivers both, combining the lifting strength of a professional crane with the road capability of a commercial truck. Unlike static lifting systems that require long preparation and setup, this equipment enables crews to drive directly to a site, stabilize the machine, and begin lifting operations within minutes. The result is reduced operating costs, faster project schedules, and unmatched versatility for companies operating under demanding conditions.

Maximum Lifting Height: 10-15m

Maximum Lifting Weight: 25t

Output: 400hp

Shaft Number: 2

Crane Jib: Three-Arm

Type: Straight Arm

Rotation Angle: 360 Degree

Outrigger Span: 2280-5100

Specification: 2260 kg

Package Size: 440.00cmx30cmx70cm

Package Gross Weight: 2200.000kg

Because the lifting unit is fully integrated into the truck mounted crane price's chassis, many contractors can travel freely on public roads without needing special escorts or permits. In Senegal, this benefit proves invaluable, as construction and infrastructure projects are often spread across multiple cities and rural areas.

The ability to complete a lift in one location and then immediately redeploy to another minimizes idle time and ensures crews remain productive throughout the day. For industries working under strict deadlines, the flexibility of a heavy duty truck mounted crane is a decisive factor when evaluating investment options and comparing truck mounted crane price ranges.

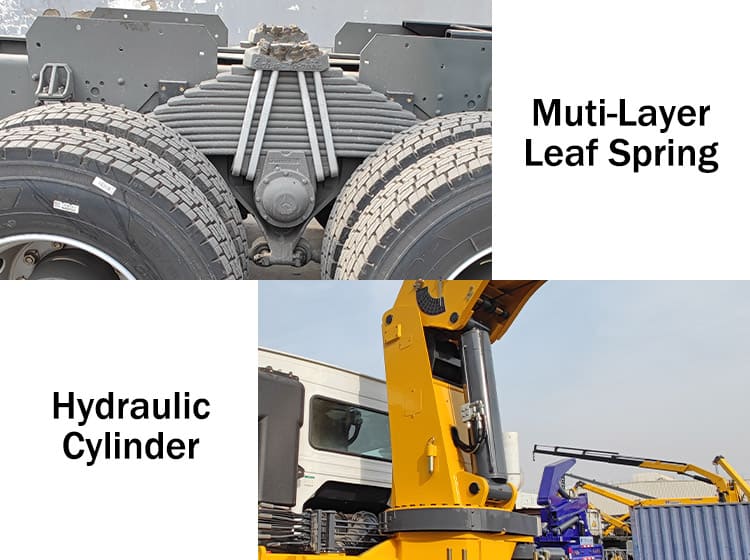

At the foundation of every machine lies the chassis. Serving as both transport platform and lifting base, the undercarriage is built from reinforced high-strength steel. Engineers add extra support at stress concentration points, preventing twisting, bending, or fatigue when the crane is pushed to its rated capacity. In the rugged and varied working environments common across Senegal, such reinforcement ensures consistent long-term performance while extending the machine's service life.

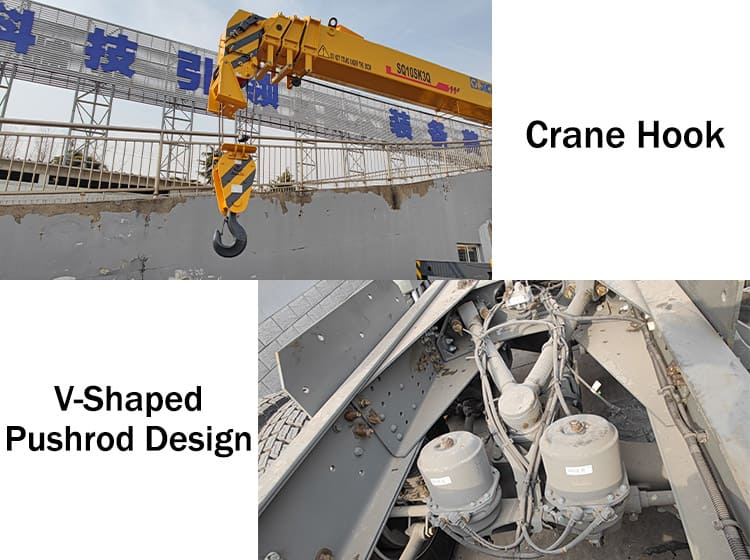

The boom is the defining feature of lifting reach and versatility. A heavy duty truck mounted crane is typically equipped with multi-section booms that extend sequentially, enabling operators to hoist materials over barriers or place loads at elevated heights without repositioning the truck.

Manufactured from lightweight but extremely durable alloys, these booms provide torsional rigidity while keeping overall weight manageable. Hydraulic extension systems allow for smooth, precise placement of cargo, an essential advantage when working in congested construction sites or on vertical building projects in Senegal.

Safety and stability are further supported by hydraulic outriggers. These extend outward from the chassis to widen the crane's footprint, preventing instability during heavy lifts. High-quality designs permit quick outrigger deployment, while more advanced models feature automatic leveling systems that adjust instantly to uneven ground.

For crews moving between narrow urban streets, uneven rural terrain, or industrial yards, these features save setup time while ensuring stability, enabling more lifts per day without compromising safety.

The hydraulic system is the operational heart of the crane. Pumps, valves, and cylinders convert engine output into precise lifting, slewing, and extending movements. Advanced designs allow multiple operations to run simultaneously, reducing work cycles and boosting productivity.

Integrated safety mechanisms, including load-holding valves, flow regulators, and pressure relief systems, prevent uncontrolled movement and safeguard both the operator and the load. For companies transporting valuable or delicate cargo, such secure hydraulic control adds confidence when reviewing truck mounted crane price options.

Operator control systems have also advanced dramatically. Many modern heavy duty truck mounted crane models include wireless remote controls, enabling operators to work from optimal vantage points with maximum visibility.

Real-time digital panels display crucial data such as load weights, boom angles, extension lengths, and safe operating radii. Having this information readily available minimizes risk, improves accuracy, and ensures every lift is performed within the equipment's rated limits.

Additional features further strengthen both safety and productivity. Anti-sway technology stabilizes suspended loads, overload alarms alert operators before limits are exceeded, and emergency stop mechanisms provide instant intervention if necessary.

Optional accessories such as auxiliary winches, working lights, and built-in storage compartments expand the range of applications, making the heavy duty truck mounted crane a multi-purpose asset. One day it may position steel beams for construction, and the next it can support utility repair after a storm.