For businesses in Senegal, it offers the ability to react quickly to shifting project needs and execute lifting operations efficiently. Combining strength, accuracy, and versatility, the crane mounted vehicle continues to serve as a fundamental solution across multiple industrial sectors.

A crane mounted vehicle answers this need by integrating the crane mechanism directly onto a commercial truck chassis, allowing operators to move efficiently between job sites while maintaining precise and professional lifting capabilities.

Rather than spending hours assembling or disassembling a static crane, crews can drive directly to the project site, deploy stabilizers, and begin operations within minutes, significantly improving productivity. In today's industrial and construction landscape, lifting and transport tasks demand machines that combine on-road mobility with dependable hoisting performance.

Crane Jib: Three-Arm

Type: Straight Arm

Rotation Angle: 360 Degree

Outrigger Span: 2280-5100

Horsepower: 340hp

Engine: Euro II standard

Cab: HW76 with new front fascia

Transmission: HW19710

For companies managing multiple dispersed worksites, this mobility translates directly into reduced downtime and lower operating costs. Construction contractors, logistics operators, utility providers, and emergency response teams all benefit from the ability to complete a lift in one location and redeploy immediately to another. This flexibility is a core reason why demand for modern crane mounted vehicles has steadily increased across diverse sectors.

In Senegal, the practical advantages of a crane mounted vehicle are further reinforced by favorable road-use policies. Many units are legally allowed to travel on public highways without the need for special escort vehicles or additional permits.

Combined with rapid setup times, this regulatory convenience enables companies to adapt quickly to shifting project priorities. Project managers overseeing multiple sites value this responsiveness, as it allows them to meet tight schedules without incurring extra logistical costs.

At the heart of every crane mounted system lies its hydraulic network. High-capacity pumps, precision valves, and robust cylinders convert engine output into smooth lifting, slewing, and telescoping motions.

Advanced hydraulics allow multiple operations to be performed simultaneously, so booms can raise, extend, and rotate at the same time, reducing operational cycles and improving efficiency. Built-in safety features, including load-holding valves, pressure relief devices, and flow regulators, ensure secure control and dependable performance even under demanding loads.

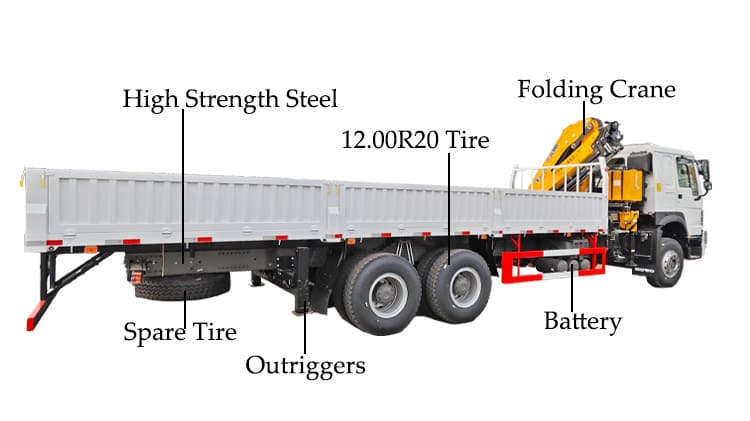

The chassis plays an equally critical role in performance and reliability. Serving as both the transport base and lifting foundation, it is engineered from reinforced high-strength steel. Reinforcements at crane mounting points help distribute concentrated forces, minimizing stress and preventing deformation or fatigue. This robust design ensures that a crane mounted vehicle operates predictably and consistently, even on the varied and sometimes rough terrain commonly encountered across Senegal.

The boom is the centerpiece of lifting capacity. Telescopic designs allow multiple sections to extend sequentially, providing the reach needed to place materials over obstacles or at elevated positions without repositioning the vehicle.

Constructed from lightweight yet high-strength alloys, modern booms balance maneuverability with exceptional torsional rigidity. Precision hydraulic extension systems further enhance load placement accuracy, reducing the need for repeated repositioning, an advantage on congested construction sites or large-scale infrastructure projects throughout Senegal.

Safety during lifts is reinforced by outriggers. These extendable supports widen the working footprint, ensuring stability even when handling heavy loads at a distance from the vehicle. Many modern crane mounted vehicles feature rapid outrigger deployment and individually adjustable legs for uneven surfaces. Advanced models include automatic leveling systems, which improve setup speed and operational stability, a critical benefit for unpredictable site conditions.

Operator control has also advanced significantly. Many crane mounted systems are now equipped with wireless remote controls, enabling operators to monitor lifts from optimal vantage points. Digital interfaces provide real-time data on load weights, boom extension, angles, and operating radii. Access to accurate information allows operators to make informed decisions, enhancing both safety and precision.

Additional integrated features further improve versatility and protection. Load moment indicators prevent overloads, anti-sway technology stabilizes suspended cargo, and emergency-stop systems provide rapid intervention in critical scenarios.

Optional accessories such as winches, onboard lighting, and storage compartments extend functionality, allowing a single crane mounted vehicle to handle a wide variety of tasks, from construction material placement to utility restoration, demonstrating the adaptability and value of modern crane mounted solutions.