Fuel tanker trailers widely use carbon steel as their primary material due to its well-established properties and excellent adaptability during manufacturing. The robust structural strength of carbon steel effectively prevents deformation of the tanker trailers for sale tank during transit, which contributes to enhanced overall stability.

By increasing the tank's wall thickness and applying advanced welding techniques, the pressure resistance of the 3 axle fuel tanker trailer tank can be significantly improved. This also enhances safety performance when the tanker trailer faces complex transportation conditions in Senegal.

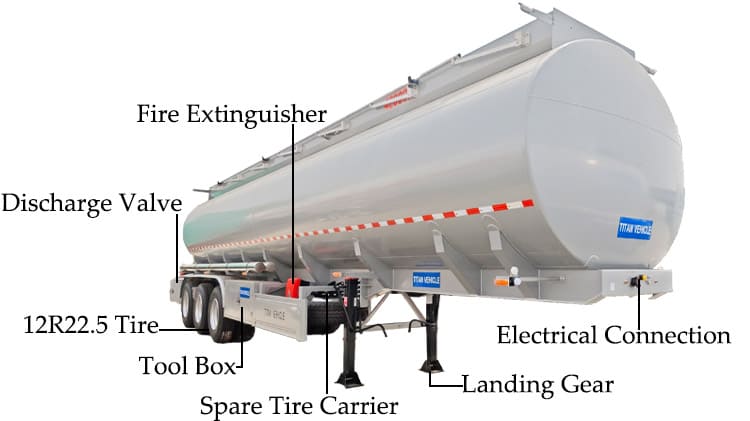

Dimension: 10600mm*2550mm*3750mm

Tanker Body Material: carbon steel

Total Volume(L): 42000 liters

Suspension: mechanical suspension

Leaf Spring: 10 layers

Landing Gear: JOST brand, 28 ton

Axle: 3 axles, 13 tons

Tire: 12 units, 12R22.5

Lamp: LED lamp with anti theft design

During the manufacturing of the 42000 liters fuel tanker trailer, advanced welding technology plays a critical role in improving weld quality and overall structural stability. The use of single-sided welding combined with double-sided forming results in stronger welds with smoother surfaces. This method effectively minimizes welding defects and completely prevents the occurrence of open welds.

Additionally, employing longitudinal welding technology ensures that welds are evenly distributed throughout the tanker trailers for sale. This even distribution improves the tank's uniformity, creates a more regular and smooth weld appearance, and reduces the risk of leaks during transportation.

The surface treatment of the tanker trailer body is carried out using an advanced powder spraying and baking painting process. Compared to traditional painting methods, this technique provides better adhesion and greatly reduces paint peeling. This results in enhanced coating durability and lowers maintenance frequency, which in turn helps customers in Senegal reduce long-term upkeep costs.

Before painting, the fuel tanker trailer undergoes multiple rounds of sandblasting and rust removal to ensure a clean surface. Following this, a three layers coating process is applied sequentially: anti-rust paint, primer, and topcoat. Under normal conditions, this treatment ensures the coating remains intact for at least five years, boosting both the appearance and corrosion resistance of the 3 axle tanker trailers for sale.

When the petrol tanker trailer carries a heavy load, the axle compression resistance becomes especially crucial. The tanker trailer model features three axles, which help evenly distribute the weight of the tank and fuel across the frame and each tire.

This balance reduces the chances of tire blowouts or frame deformation caused by excessive localized pressure. Additionally, combining these axles with a heavy duty mechanical suspension effectively cushions vibrations and impacts from Senegal varied road conditions.

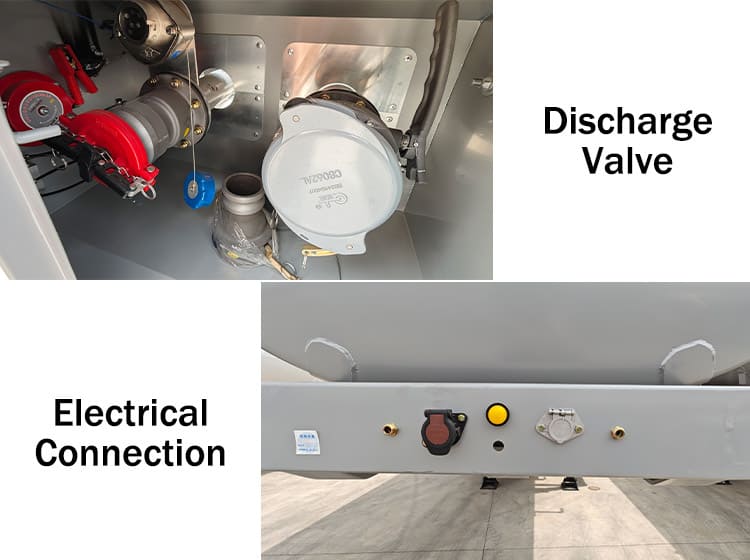

To accommodate various customer needs, the unloading port on the fuel tanker trailer can be flexibly positioned on either the left or right side. The tanker trailer also offers a compartmentalized tank design, dividing the tank into several independent sections. This layout helps buffer the impact of fuel shifting inside the tank, improving both stability and transportation safety.

For larger capacity fuel tanker trailers, internal thickened wave-breaking plates are installed to reduce the movement and shaking of fuel during driving. This further protects the cargo and the tank itself from potential damage.

After production, the 42000 liters tanker trailers for sale undergoes stringent testing to ensure its safety and sealing performance. High temperature pressure tests are conducted to verify whether oil and gas volatilization might occur under elevated temperatures, thereby guaranteeing safe driving and parking conditions for the tanker trailers for sale during local use. In addition, water injection tests are carried out to check the tank's sealing integrity, eliminating the risk of oil leakage throughout transportation.

Before shipping, TITAN applies a protective wax coating to all fuel tanker trailers, which serves as an anti-corrosion layer. This wax protects the tanker trailer surface from the damaging effects of salty sea air and moisture, common in marine environments. Furthermore, all tanker trailers for sale are carefully packed with waterproof rain covers prior to delivery.

This packaging reduces the risk of surface damage caused by exposure to harsh weather conditions during shipping. Through this comprehensive protection process, TITAN ensures every