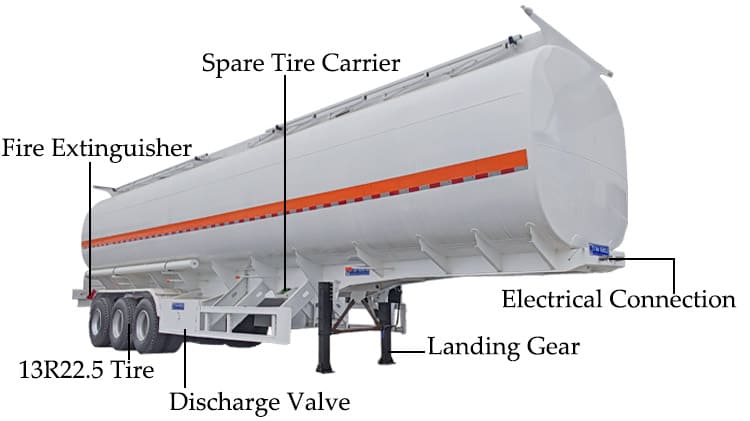

The 3 axle stainless steel tanker is a specialized transport vehicle designed for carrying hazardous, flammable, and explosive liquids. It features a fully sealed tank structure that complies with strict safety standards. TITAN, as a diesel tanker manufacturer, applies a modular design approach to tank production.

In addition to standard capacity configurations, Senegal customers can choose customized options such as tank capacity adjustments, optimized tank materials, and tailored chassis structures. This flexible configuration allows the diesel tanker trailers to be adapted to specific regional transport environments and to serve operations of various sizes.

Dimension: 11700mm*2500mm*3800mm

Total volume(L): 45000L

Tanker Body Material: stainless steel

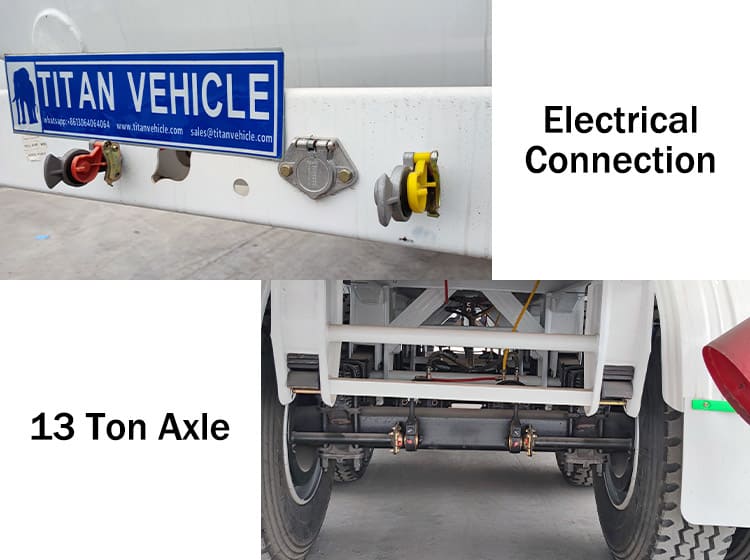

Axle: 3 axles TITAN brand

Landing Gear: 28 ton

Suspension: mechanical suspension

Leaf Spring: 10 layers

Tire: 12 units, 13R22.5

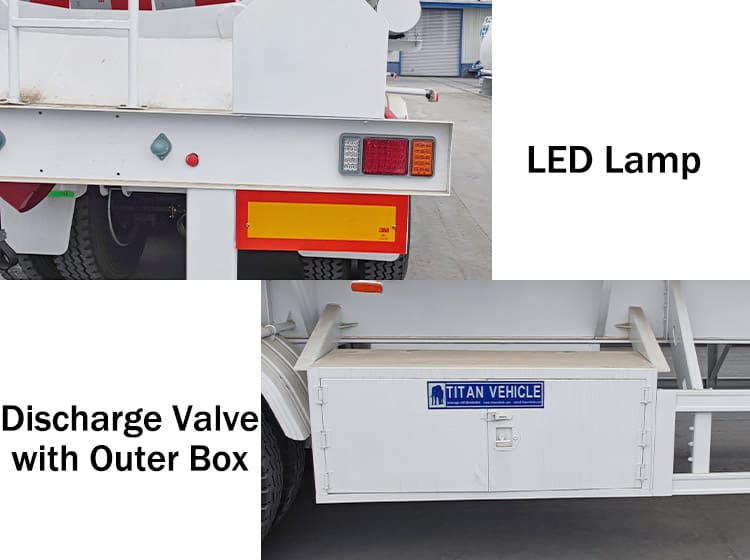

Lamp: LED Lamp

The unloading system of TITAN's 3 axle stainless steel tanker for sale is also based on a modular concept. Discharge valves can be installed on either or both sides of the trailer, depending on the operational requirements of different countries. For the 45,000-liter diesel tanker model, the tank is divided into sub-compartments to improve loading efficiency through scientific volume distribution. This design also supports personalized configurations for customers in Senegal.

For large volume fuel transport, the diesel tanker is equipped with an internal buffering system. Wave-breaking boards inside the tank help distribute the liquid's dynamic force during movement, protecting both the tank structure and the transported fuel. This dual protection approach is especially important for maintaining stability and safety when the stainless steel tanker is in motion.

The suspension system is another area where TITAN has applied structural innovation. The mechanical suspension uses high strength steel leaf springs arranged to create a multi-stage buffering effect. This greatly reduces vibration transmission when traveling over Senegal's unpaved roads.

In addition, the use of a 70mm center balance pin enhances diesel tanker price balanced stability, reinforcing the surrounding frame structure. This design protects the transported fuel from unnecessary agitation and reduces wear caused by challenging road conditions.

To ensure long-lasting protection, the surface of the 45,000 liters stainless steel tanker for sale undergoes a composite coating process. This involves powder spraying followed by baking, combining visual safety benefits with improved durability.

High adhesion coatings help maintain a clean appearance and protect against environmental wear over time. Before this coating is applied, the diesel tanker price receives multi-step surface treatment, including anti-rust paint, primer, and topcoat application. This multi-layer approach extends the service life of the diesel tanker and reduces future maintenance costs.

Stainless steel is widely chosen for petrol tanker manufacturing due to its combination of durability and adaptability. This material offers strong resistance to fuel-induced corrosion, making it suitable for long term use.

When the stainless steel is made thicker, its ability to resist corrosion is further enhanced, enabling the stainless steel tanker for sale to operate reliably even in demanding conditions. It also maintains its shape under high temperatures, ensuring the tank structural strength is preserved both internally and externally.

The welding process plays a key role in maintaining the integrity of the tank. TITAN uses an improved welding method that combines single-sided welding with double-sided forming, which helps eliminate common defects found in traditional welding.

Longitudinal welding is applied to the main joints of the tank, ensuring uniform stress distribution and improving both sealing performance and structural strength. This advanced approach provides a strong technical foundation for safe fuel transport.

The axle configuration of a diesel tanker price plays an essential role in managing load distribution. With its three-axle setup, the tanker spreads the weight of the cargo evenly across the frame and tires. This even distribution helps reduce the risk of tire blowouts and frame distortion when occur too much stress , ensuring safer and more stable transportation in Senegal.

Before shipment, TITAN applies a dual protection system to every 45,000 liter stainless steel tanker for sale. Each unit is coated with protective wax and covered with waterproof fabric to shield it from high salt spray during sea transport. This packaging method is more protective than the conventional processes used by many other manufacturers, forming a distinctive quality assurance system for the transportation stage.