Modern lifting and transport projects increasingly demand equipment that can move quickly between sites while still offering strong and precise hoisting capabilities. A lorry mounted crane meets this requirement by merging on-road mobility with professional-grade lifting power.

Because the crane is fully integrated into the vehicle chassis, crews can drive directly to a job site, deploy the supports, and start work immediately, without the delays that come with assembling or disassembling fixed lifting systems.

Crane Jib: Three-Arm

Type: Straight Arm

Rotation Angle: 360 Degree

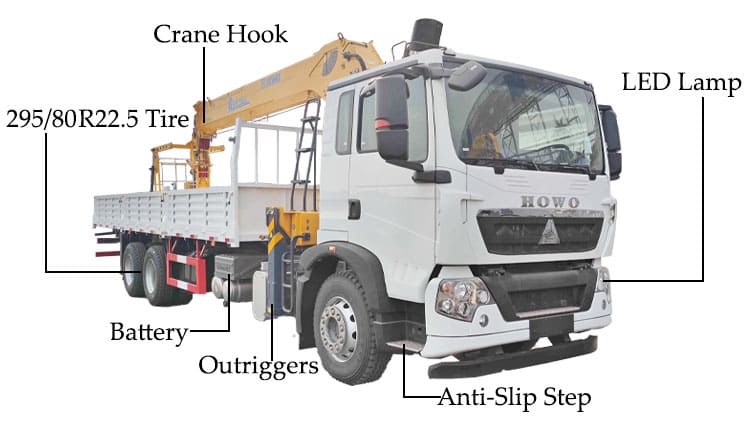

Outrigger Span: 2280-5100

Horsepower: 330hp

Engine: Euro II standard

Cab: HW76 with new front fascia

Transmission: HW19710

For businesses managing operations across multiple locations, this mobility reduces downtime and transport costs, two of the biggest concerns in construction, logistics, utilities, and emergency services. With a mounted crane truck, operators complete a lift in one area and redeploy to another within the same day, maximizing efficiency. This ability to remain flexible is a decisive reason why the mounted crane is becoming an increasingly popular choice across industries.

In Senegal, the practicality of the lorry mounted crane is reinforced by road regulations that allow many units to travel freely on highways without requiring special escorts or permits. Combined with its rapid setup process, this regulatory advantage lets companies respond to changing project needs almost instantly.

Project managers in regions with dispersed job sites value this capability highly, since it allows them to complete lifts on tight schedules without incurring additional costs.

At the heart of the machine is the hydraulic system, which transforms engine power into controlled lifting, slewing, and extension. A modern mounted crane uses advanced pumps, valves, and cylinders to achieve smooth, multi-function operation. This means the boom can raise, extend, and rotate at the same time, significantly cutting operational cycles.

Built-in safety devices, such as load-holding valves, pressure relief mechanisms, and flow regulators, add reliability and prevent sudden or dangerous movements, even during heavy-duty lifts.

The chassis of a mounted crane truck plays an equally crucial role. Constructed from reinforced high-strength steel, it serves as both the transportation base and the lifting foundation. Engineers add reinforcements around crane mounting points to distribute concentrated forces and minimize deformation or fatigue. Thanks to this structural integrity, the lorry mounted crane maintains predictable performance under load, even when operated frequently on the varied terrain found in Senegal.

The boom remains the centerpiece of lifting ability. Telescopic sections extend sequentially, providing the reach required to move loads over barriers or to elevated positions without moving the vehicle itself.

Modern booms are manufactured from lightweight, high-strength alloys, ensuring torsional rigidity while keeping overall weight manageable. Hydraulic extension systems allow for precise placement, reducing the need for repeated repositioning and enhancing productivity on congested job sites across Senegal.

Safety during lifts is maintained by outriggers. These extendable supports widen the machine's base, ensuring balance when handling loads at a distance. Quality mounted crane models allow rapid outrigger deployment and offer individual leg adjustment, so operators can stabilize the vehicle even on uneven ground. Some advanced designs also feature automatic leveling systems, which provide quicker setup and improved safety—a vital advantage when crews must adapt to unpredictable site conditions.

Operator control systems have advanced considerably in recent years. Many lorry mounted crane models are now equipped with wireless remote controls, giving operators the ability to stand at optimal vantage points during lifts.

Digital displays provide real-time data, such as boom angle, load weight, and operating radius, ensuring that lifts remain within safe parameters. These improvements not only enhance accuracy but also reduce risk, creating a safer and more efficient workflow.

Additional integrated systems expand both safety and versatility. Load moment indicators prevent overload situations, anti-sway technology stabilizes suspended cargo, and emergency-stop mechanisms offer instant shutdown in case of anomalies.

Optional features, such as auxiliary winches, work lighting, and built-in storage compartments, further extend the capabilities of a mounted crane truck. This versatility allows one machine to handle diverse tasks, from construction projects to disaster recovery, making it an invaluable asset for companies that require reliable, multi-purpose equipment.